Why Supply Chain Maturity Matters

Oct 14 2015

This article challenges you to review your organization’s level of supply chain maturity, and gives you an introduction to a new framework that will help you achieve an agile ‘one-business’ approach that will deliver ongoing competitiveness and improved overall profit.

Guest Post by James Feeney

How did your business grow to be successful?

Most companies’ point of difference is based on a unique product, process, cost advantage, or maybe targeting a set of customer needs not met by existing industry participants. Inevitably over time, competitive positions erode, and in an effort to keep up with the changing competitive landscape, businesses frequently develops reactive and compartmentalized approaches that ultimately reduce your competitiveness and overall profit.

Tell-tale signs you are at the wrong level of supply chain maturity

There are all sorts of reasons businesses fail to reach the right level of maturity. Market sectors evolve, customer needs change, or strategies are not aligned to supply chain and operating models. Whatever the cause there are a few tell-tale signs to watch out for:

- Stale market position

- Being “all things to all people”

- Can’t say no

- Poor responsiveness

- Failing to meet customer needs

- Inconsistent operational strength

The Supply Chain Maturity Model

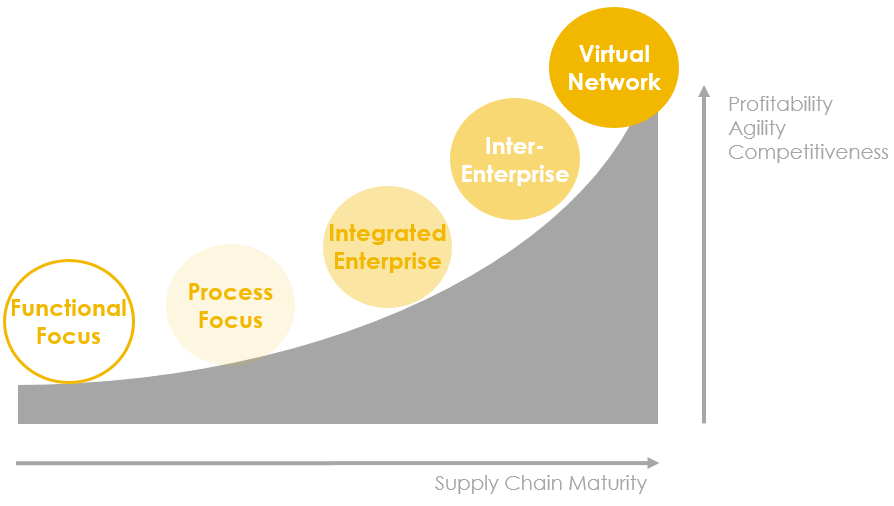

Generally speaking, companies progress through stages of maturity with their supply chain strategy and structure. The requirements differ across markets, and the target maturity level of a company will depend on the industry sector it competes in, the demands of customers in that sector, and their particular ‘competitive position’ in that market.

A company at the right level of maturity will have an agile “one-business” approach, where clear strategies can be readily defined and applied and the organization – and entire supply chain – is highly aligned in support of these strategies.

5 Stages of Maturity

Broadly speaking there are 5 stages of maturity. To underpin future strategy, all businesses should first understand what the current level of maturity is, and then define what level the business needs to be at.

Companies can ‘mature’ across these levels, to reach the optimum stage that suits their industry structure and market position. For example, a company may define itself to be currently at ‘Stage 1’ Level maturity (with a ‘Functional/Silo’ focus), but may agree that it needs to progress to Level 4 Maturity (Integrated Enterprise). This ‘gap analysis’ then forms the basis of their future supply chain strategy.

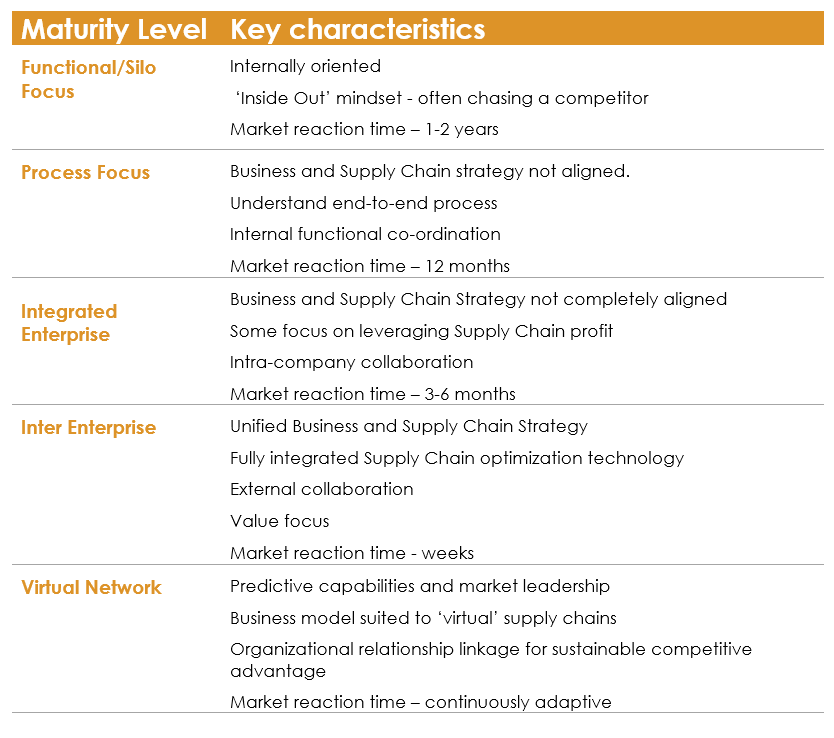

Key Characteristics

There are many factors that indicate how mature the business and supply chain is, but each level has a few key characteristics:

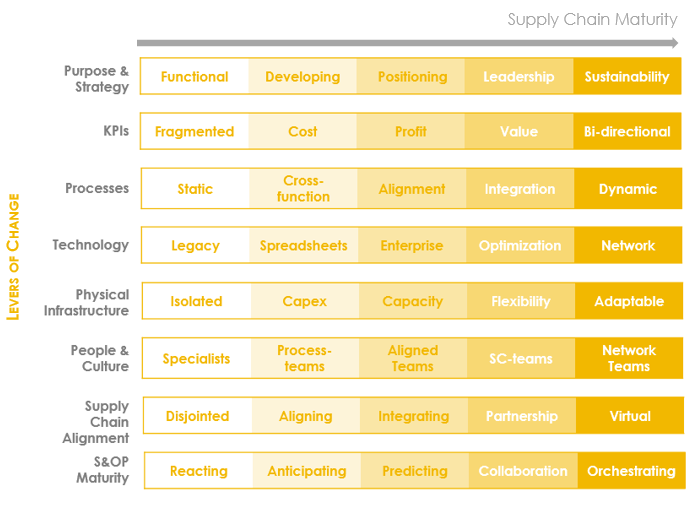

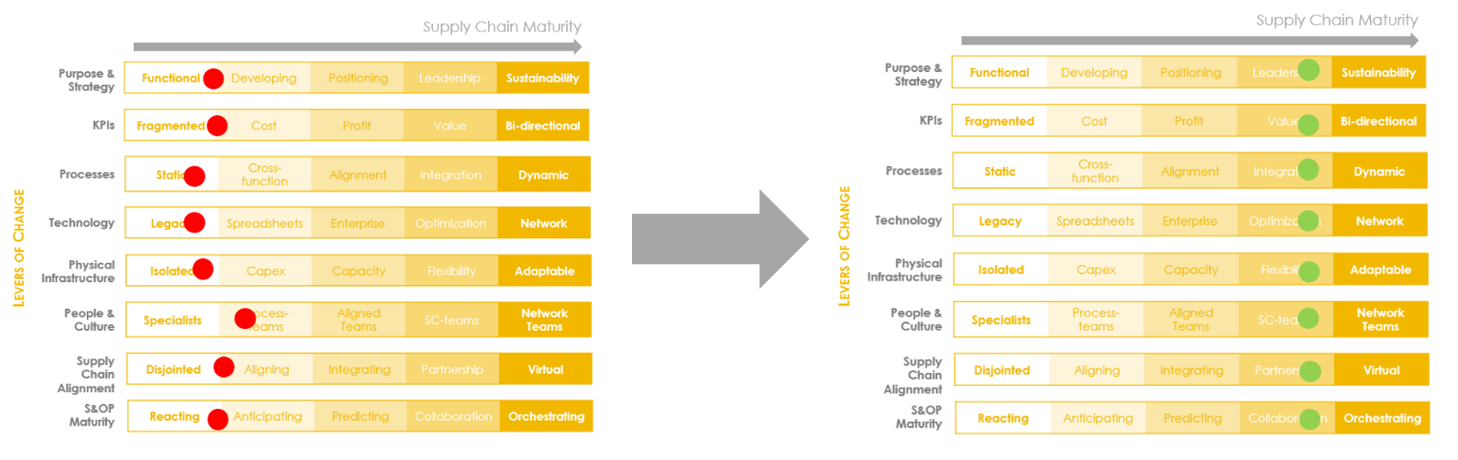

Levers of Change to achieve Supply Chain Maturity

There are 8 ‘levers of change’ that can be used to assess your current level of business and supply chain maturity, identify your target level of maturity, and then to identify the strategies and actions needed to ‘close the gap’.

Eight Levers of Change

Each of these levers reflects different characteristics at each stage. Drilling down into one of the levers – taking “People & Culture” as an example, a business can progress from Specialists to Network Teams at different stages:

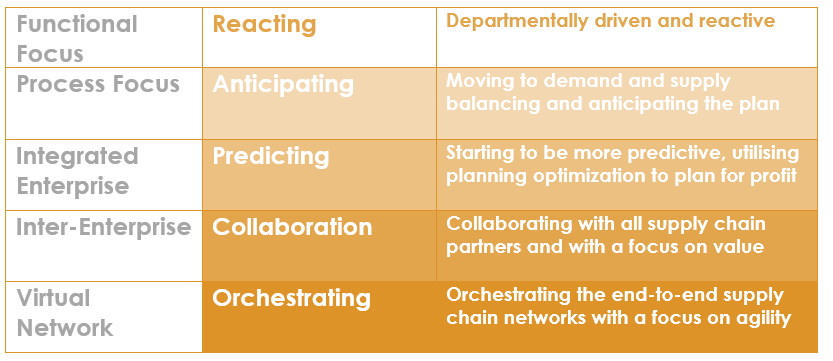

So from an S&OP perspective companies can mature in the following way:

Defining your Target Level of Maturity

Before defining your target level of maturity you need to first understand where you are across all 8 levers of change.

Of course, this is easier said than done. To really understand where you are at, requires proper analysis with input from the senior executives responsible for the individual levers of change. A full analysis at this level should highlight where the major areas of development are required to take the company to the target maturity level.

Transition to your Target Level of Maturity

The process should include:

- Completing a gap-analysis between the current state of the supply chain and the future vision

- Defining a range of strategic objectives to bridge the gap

- Developing the strategies

- Assessing priorities

- Taking Action

Underpinning Business Strategy

In a company with a non-aligned business and supply chain strategy they might, for example, build rigid volume and cost-focused operations that cannot deliver the responsiveness / flexibility needed by market (or alternatively they may build in uneconomic flexibility – and fail to compete on cost…)

By implementing fully aligned business and supply chain strategy you will see the following improvements:

- Customer service – as the supply chain is aligned cost-effectively to deliver customer needs

- Internal culture – as company, department and personal KPIs align to create ‘one company’ goals

- Simplicity – as rationalized products and customers usually result in simpler delivery model

- Cost reduction – as supply and demand become balanced, the end-to-end supply chain can be optimised with overall profit in mind (lower inventory levels, more effective manufacturing, less demand on warehousing and logistics, more effective procurement etc

- Enhance planning and optimization capability – as the supply chain and its partners are integrated with improved S&OP and enabling technology.

While progressing to your target level of business and supply chain maturity requires commitment and strategic leadership, you will start reaping benefits well before you reach your target. Findings from the analysis stage make a major contribution to and underpin business strategy, whilst helping to crystallise the true nature of an organization’s competitive advantage.

When business and supply chain strategy is effectively aligned and integrated across the eight levers of change, then all supply chain participants (from customers to suppliers) benefit. Flow on improvements in customer retention, and increases in sales, profit and enterprise value inevitably follow.

I’m always happy to chat to businesses about ways to improve their supply chain maturity. Don’t hesitate to contact me via email or phone if you’d like to find out more. Alternatively contact ComActivity to find out how they may be able to assist with your supply chain strategy.

Supply chain expert, James Feeney, is a specialist in delivering business-focussed solutions to the supply chain sector. Drawing on over 20 years of global experience across a diverse range of industries including food processing, manufacturing, financial and government, James is a specialist in supply chain diagnostic methodologies and tools which help refine operations strategy and target key areas of focus where business decisions and tools can add enormous value to operational effectiveness. James is currently Managing Director of Optimity New Zealand.

Supply chain expert, James Feeney, is a specialist in delivering business-focussed solutions to the supply chain sector. Drawing on over 20 years of global experience across a diverse range of industries including food processing, manufacturing, financial and government, James is a specialist in supply chain diagnostic methodologies and tools which help refine operations strategy and target key areas of focus where business decisions and tools can add enormous value to operational effectiveness. James is currently Managing Director of Optimity New Zealand.

Contact James to find out more about reviewing your supply chain maturity:

e: james.feeney@optimity.co.nz

ph: +64 21 276 0176

FOLLOW

FOLLOW